System voltage: | 30kV≤U≤500kV |

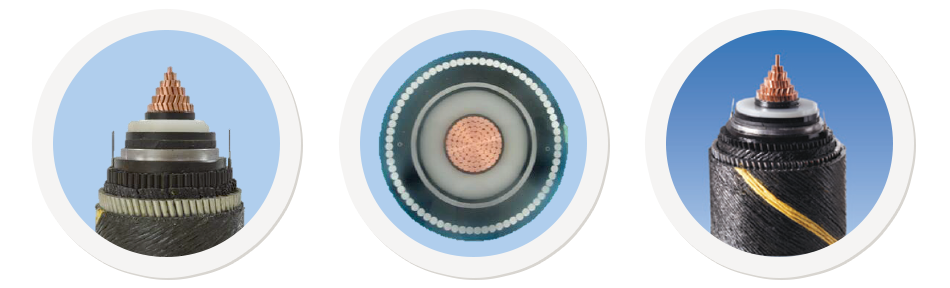

Conductor: | Circular stranded copper conductor constructed of round or profiled wires. |

Max. CSA 3000sq.mm | |

Insulation: | Cross-linked polyethylene (XLPE) |

Metallic Screen/Sheath: | Lead alloy sheath |

Armor: | Galvanized steel wire |

Armor bedding & serving: | Polypropylene yarns |